Essential Guide to Post and Beam Steel Construction: Durability and Design Explored

When it comes to building durable structures with an eye for design, post and beam steel construction is unrivaled. Its unique combination of rigidity and flexibility makes it a preferred option in modern construction.

This article answers critical questions about this method, from materials and processes to design advantages, helping you understand why it excels in creating both sturdy and aesthetically pleasing buildings.

Key Takeaways

Post and beam steel construction adheres to stringent standards like those of the NBC to ensure safety and compliance, and involves processes like cold forming and welding to create strong structures measured in Newtons.

Post and beam architecture offers significant design flexibility, allowing for open-plan spaces, large windows, and adapting to varying aesthetic requirements while ensuring robust structural support through elements such as beams, columns, and diagonal braces.

In post and beam structures, durability and functionality are achieved by using high-strength materials like structural steel, managing loads through carefully designed roof and wall systems, and integrating mechanical and electrical systems without compromising the structural integrity.

Exploring Post and Beam Steel Construction

The process of post and beam steel construction is an intriguing and critical component in contemporary architecture. In this method, raw materials are meticulously transformed into complete structural components through a series of fabrication steps that include:

Cutting

Punching

Welding

Cleaning

Painting

Such carefully conducted procedures result in the creation of strong structures designed to resist substantial forces, quantified by the SI unit known as NEWTON (N).

It’s imperative to recognize that this method follows strict guidelines regulated by the National Building Code (NBC). The compliance with such stringent standards is vital within post and beam steel construction practices, emphasizing not just precision but also unwavering adherence to safety protocols.

The Anatomy of Post and Beam Structures

The foundational elements of post and beam architecture are the vertical columns, which serve as crucial components standing upright.

These columns bear the responsibility for channeling loads from essential roof structures such as beams, trusses, or rafters directly down to the foundation, ensuring the roof surface structural integrity is maintained.

The sides of openings within this construction type feature jambs – another set of vertical framing members that provide reinforced support.

Beams running horizontally form an integral part too. They resist bending forces exerted upon them. Three distinct kinds exist: simple beams with a span between two supports, continuous ones extending over multiple supports, and cantilever beams projecting outwards without intermediate support on one end.

The strength displayed in these constructions comes from a harmonious integration between both types of structural elements (those aligned vertically like vertical framing members along with horizontal mainstays) bolstered by specialized leveling and bearing plates critical for apt load distribution and sustenance horizontal structural member.

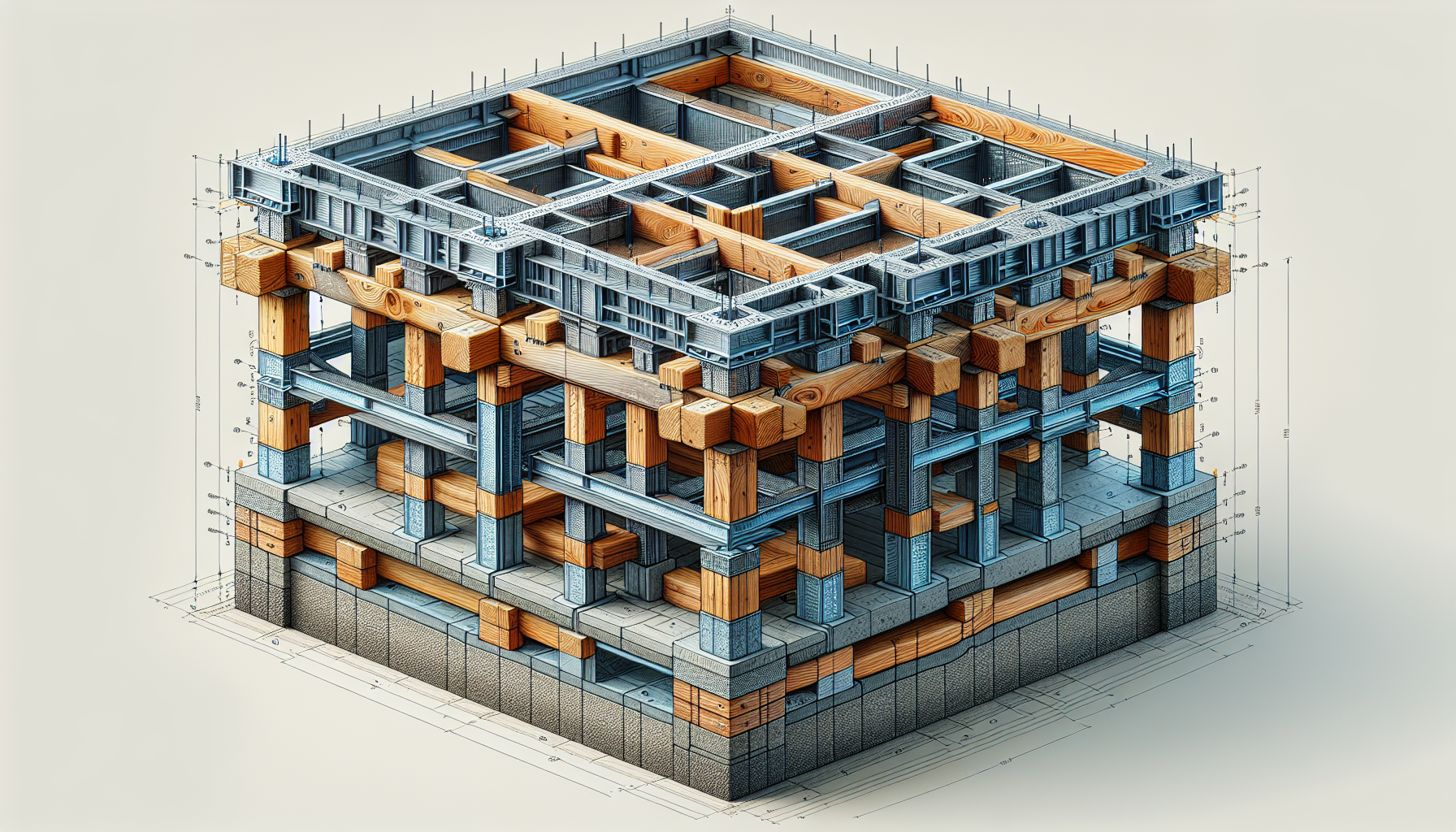

Materials Used in Post and Beam Construction

Post and beam structures derive their robustness and longevity largely from the high-quality materials employed in their construction. Structural steel is a prime component, renowned for its superior strength with a yield exceeding 36,000 pounds per square inch while being able to endure tensile stress above 100,000 pounds per square inch.

Thanks to these properties, structural steel can support substantial loads without compromising stability or integrity.

In erecting such edifices, pre-engineered metal building systems are utilized that incorporate both built-up structural frames made of structural steel and secondary components known as cold-formed structural steel members,—either fashioned from cold-formed steel or taking the form of steel joists.

The use of metal fasteners and connectors differentiates post and beam constructions from those using timber frames. These materials not only enhance efficiency but also bring down costs by streamlining engineering tasks and fabrication processes, which consequently reduces the need for highly skilled labor within these specialized metal building systems.

Key Elements of Post and Beam Design

The post and beam architectural approach offers remarkable aesthetic versatility, which is evident in features such as:

Expansive windows

Diverse room configurations without the reliance on load-bearing walls inside

The hallmark open-concept layouts that are synonymous with post and beam homes

This design’s flexibility is amplified through the use of substantial vertical framing members located and spaced at considerable distances.

The beauty of a post and beam structure isn’t just skin deep. It also possesses inherent structural strength. This foundational system bolsters artistic expression within architecture, affording adaptability for an array of design preferences.

Metal connectors serve a dual purpose in this regard: they can be exposed as decorative elements or hidden away to preserve particular visual goals.

Even roof designs play a role both aesthetically and structurally in these buildings—with their numerous peaks and troughs not only making bold architectural statements but also assisting in supporting loads effectively.

Structural Support Projecting Strength

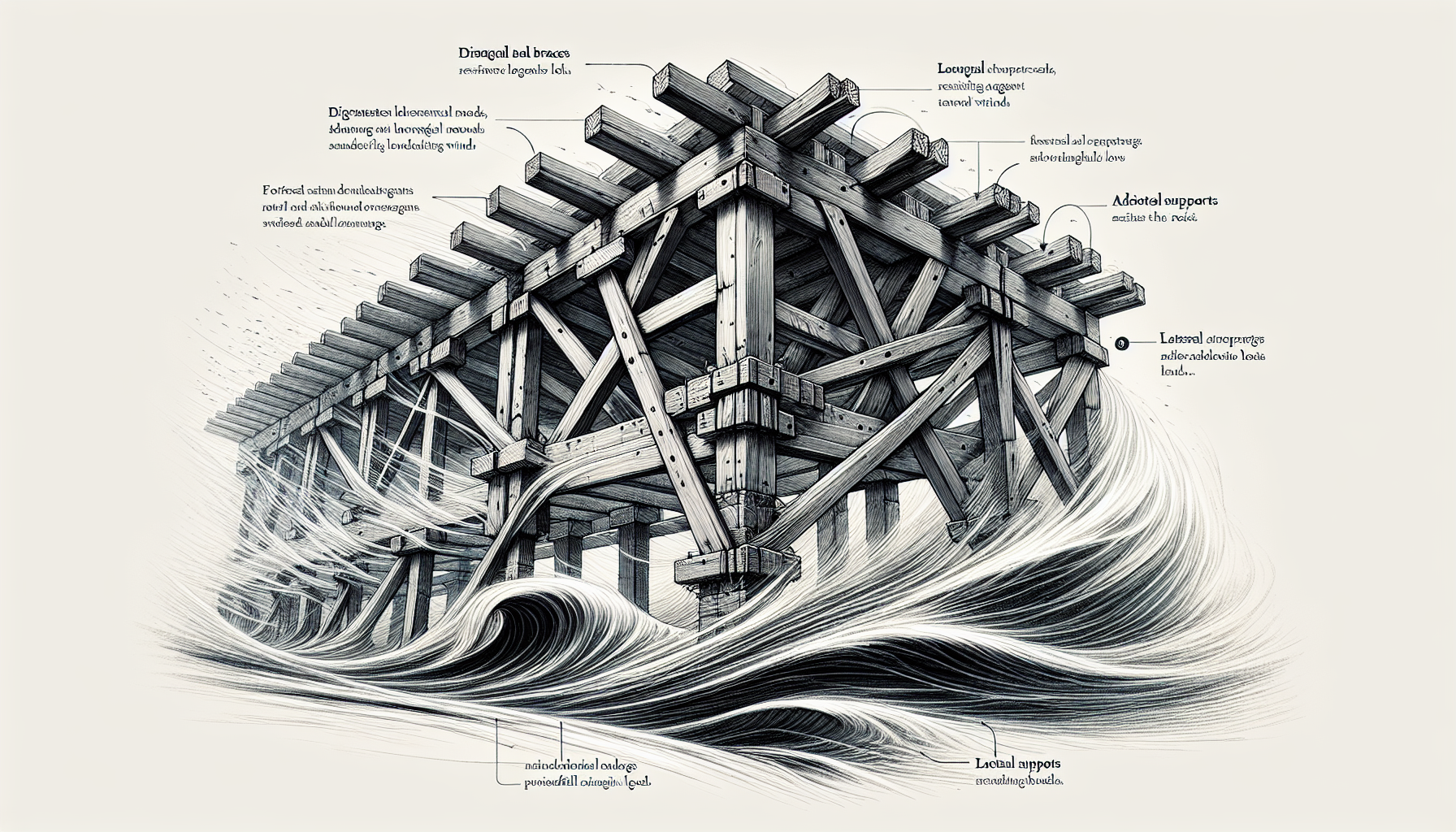

The design of post and beam structures is primarily focused on projecting strength through robust structural support. This is accomplished in part by incorporating diagonal braces that adeptly transfer lateral loads to vertical member.

Additional stability comes from the strategic integration of posts, beams, and shear panels, which collectively fortify the structure.

Due to its adaptable nature, post and beam construction permits the development of expansive areas featuring elevated ceilings without relying on load-bearing walls for support.

This architectural approach ensures that post and beam buildings can offer sturdy reinforcement for roof loads while simultaneously permitting movement both horizontally and vertically. The synthesis of these features results in a resilient edifice designed to withstand substantial forces.

Customizing Design With Metal Building Systems

Post and beam construction offers flexibility that encompasses the integration of metal building systems for custom designs.

By utilizing connections between modules, these steel structures can be designed to meet particular architectural requirements while effectively distributing loads without compromising spatial and structural integrity.

Personalizing a design comes with economic implications. It is essential to communicate cladding specifications to the provider of the building system at an early stage to guarantee consistency with budgetary limitations.

Early participation in this way facilitates precise cost forecasting and helps keep the project financially manageable.

Implementing Mechanical and Electrical Systems

Post and beam construction is robust enough to allow for the integration of mechanical and electrical systems. These vital services, including HVAC and plumbing, often require that holes be made in structural components.

Prefabricated modular buildings are commonly utilized in steel constructions to preserve the architectural integrity during on-site assembly of these systems.

When installing HVAC systems into metal structures, specific factors are carefully evaluated. The influence of sources generating heat within the metal building system is factored in so that thermal requirements are adequately addressed.

In scenarios where metal buildings function as workshops, displacement ventilation becomes a key method for sustaining both air quality and temperature regulation.

Accommodating Systems Without Structural Compromise

Incorporating mechanical and electrical systems into post and beam buildings requires a careful equilibrium.

Structural engineers must work in tandem with mechanical engineers, sharing data regarding load demands and the configuration of structures to confirm that these installations do not detract from the integrity of structural frame of the building.

Radiant heating systems beneath the floor are frequently implemented in constructions using post and beam methods as they offer options beyond conventional sheathing while preserving the open-space design ethos.

Utilizing a Building Information Modeling (BIM) strategy for design promotes efficient synchronization among various system components.

This collaborative process helps identify and address any potential complications early on during design stages, ensuring seamless integration of systems without infringing upon structural elements.

Roof Structures in Post and Beam Buildings

Focusing on the uppermost sections, we explore roofing systems within post and beam construction, particularly those featuring multiple gable buildings.

Characteristically, these structures sport gable roofs recognized by their peaked design culminating in triangular end walls called gables. Integral to both function and form of the above roof system are elements such as:

rake

valley gutters

ventilators

flashing

Each plays a pivotal role not only in ensuring proper structural performance but also in enhancing visual appeal.

The integration of HVAC systems into the roofing architecture of post and beam edifices must address specific challenges like load-bearing limitations and unique space requirements for installation.

Hence, the roof is much more than just a shield against external elements. It forms an essential component that contributes to both operational efficacy and comprehensive architectural stability.

Roof Slope and Snow Load Considerations

In post and beam structures, the angle of the roof is a critical factor in coping with snow loads. Properly designing this slope promotes efficient distribution dead load and removal of snow, safeguarding against potential damage to the structure.

For determining suitable ground snow load values at a building location, one must refer to either the International Residential Code (IRC) or ASCE 7-16 standards.

For constructions handling ground snow loads up to 70 pounds per square foot (psf), builders can reference span tables provided by the IRC or those for engineered lumber.

In situations where ground snow loads exceed 70 psf or if a roofing system extends beyond what’s covered by IRC guidelines, consulting a structural engineer becomes essential for compliance with ASCE 7-16 standards—highlighting that effective management of snow loads hinges on thoughtful design and strict adherence to recognized codes.

Types of Roof Covering and Panels

Roof panels and coverings are essential for both the look and effectiveness of post and beam constructions. R-Panel or Multi-Rib panels, crafted from 26-gauge steel with durable coatings like SMP or PVDF, are often chosen as roofing and siding options.

For barn-style dwellings (barndominiums) constructed using post frame techniques, typical agricultural panels such as Max-Rib and Mesa made from lighter 29-gauge steel provide an appealing look along with functional benefits.

As alternatives to standard roof coverings:

Distinctive corrugated styles like Multi-Cor or M-Cor can deliver a personalized aesthetic suited for post and beam frameworks.

Wave panel systems that conceal fasteners create smooth wall surfaces.

Standing seam choices like Meridian offer elegant solutions for roofing requirements.

Such variety in coverage contributes significantly to improving both the facade and efficiency of these buildings.

The assortment of design patterns, inclinations towards various slopes, plus a spectrum of hues offered by metal roofs enables personal tailoring to meet individual taste preferences alongside energy-saving needs.

Wall Systems Complementing Post and Beam Frames

The wall systems, integral to the robustness of post and beam frames, are essential for the structure’s integrity.

They encompass a variety of components such as exterior wall panels that cover the framework, along with their attachments like sheets, trim fascia plus weatherproof sealants which work together to create a secure barrier.

Included within this system are several important features:

Closure strips serve an important function in sealing off gaps where metal panels meet flashings, delivering an environment free from air and water infiltration.

Parapets rise above where walls meet roof lines not just adding to structural soundness but also enhancing aesthetic appeal.

Adaptable door configurations can be assimilated into standard wall framing accommodating design requirements ranging from expansive picture windows to sliding glass doors for versatile use.

Perimeter Wall Panels and Insulation Integration

The successful execution of post and beam construction relies heavily on the incorporation of perimeter wall panels with insulation to ensure peak functionality.

It’s important for maintaining efficient heating, ventilation, and air conditioning (HVAC) operations as well as effectively managing moisture within the structure.

A high overall R-value is achieved by combining foil-faced polyisocyanurate insulation with continuous foam that sits over the top of the structural wall framing system and materials. This approach also minimizes thermal bridging while bolstering insulation performance.

When installing these perimeter wall panels:

Utilizing joints that are offset plays a critical role in diminishing air leaks and elevating the building’s resistance to outside elements.

Wrapping an unbroken layer of insulating material around the frame’s exterior ensures an impermeable barrier against air intrusion.

The likelihood of condensation forming inside the walls is greatly diminished because of this wrap.

In terms efficiency concerning thermal regulation, it performs better than typical 2x6 framed walls.

Enhancing Stability Against Wind Loads

The structural integrity and enduring stability of post and beam steel construction hinge on comprehensive planning to combat horizontal wind loads.

The resilience of the structure against these forces is augmented by a variety of components.

Portal frames are implemented to withstand longitudinal wind forces, especially when the use of diagonal bracing isn’t an option. Simultaneously, wind columns are engineered as vertical supports that fortify wall systems from such pressures.

To counter lateral forces of wind load, continuous frames incorporate moment-resisting connections along with supplementary members.

Alternatively, knee braces provide angled reinforcement designed specifically to diminish the impact of horizontal winds.

An integrated approach involving portal frames, wind columns, continuous frames, and knee braces is essential in strengthening post and beam structures against the variable intensities posed by wind loads.

Strategies to Resist Longitudinal Loads

In post and beam construction, combating horizontal forces requires methods including:

Providing sufficient end bearing to avert the collapse of beams

Guaranteeing that loads are evenly distributed to avoid crushing at points of support, which in turn assists in supporting vertical loads

Aiding in maintaining the complete stability of the edifice.

Foundation and Floor Systems in Post and Beam Construction

Investigating the core elements of post and beam architecture, we examine the foundational and floor systems integral to these structures.

The foundation serves as an essential component that carries both vertical and horizontal forces, providing a solid base for the structure’s entirety.

In order to distribute structural loads effectively across the ground, footings are utilized in the construction process. Anchor bolts are indispensable in securing members of the structure firmly to its foundation.

To facilitate effective distribution of weight through the main frames down into this groundwork is where secondary beams or purlins come into play.

As such, both foundational and flooring systems comprise vital aspects of post and beam construction by supporting its whole framework, which ensures overall stability within these structures.

Concrete Structure Designed for Uniform Bearing Surfaces

In the realm of post and beam construction, achieving uniform bearing surfaces is a critical component in designing concrete structures to adequately distribute structural loads.

The application of grout—which comprises cement, sand, and water—is indispensable for creating uniform bearing surfaces by filling voids and sealing fissures.

Employing this mixture beneath base or leveling plates is an essential process that establishes a flat and secure platform for the subsequent installation of steel structures.

Consequently, the thoughtful design of concrete elements within post and beam architecture is paramount in upholding stability and ensuring long-term integrity.

Secondary Framing and Support Elements

Support elements such as girts, purlins, and eaves struts play a significant role in bolstering the stability of post and beam structures by serving as secondary framing.

Purlins are specifically tasked with transferring roof loads to the primary structural members, reinforcing support throughout the structure.

In order to preserve the cohesive strength of post and beam joints, metal brackets and steel plates are indispensable for connecting timber components effectively.

Secondary framing members serve as conduits for distributing forces within post and beam constructions towards primary supports, thereby markedly increasing both the robustness and stabilization of these architectural frameworks.

The Role of Secondary Framing in Load Distribution

Components of secondary framing, including girts and purlins, are integral in redistributing loads to the principal structural elements, facilitating efficient load dispersion.

Within this secondary framework, jack beams provide crucial support for additional beams or trusses by obviating the requirement for columnar support, which contributes significantly to uniform load sharing.

The significance of these components within a post and beam construction is highlighted by their capacity to carry loads.

This underscores the critical nature of secondary framing in maintaining both the stability and structural soundness of such edifices.

Access and Egress Solutions

Various door mechanisms are employed to facilitate ingress and egress in post and beam steel structures, including:

Hydraulic doors that offer an unobstructed overhead entry without diminishing clearance

Steel bi-fold doors providing expansive openings suitable for large access areas like those found in aircraft hangars

Stack doors which save space by horizontally aligning panels when open

Rolling doors that present a robust and compact option, particularly well-suited for locations with limited surrounding space

These systems are designed to provide straightforward and efficient access into and out of buildings.

For operations requiring less dependence on electricity or manual handling, stack doors emerge as a substantial alternative within the realm of steel edifice portals.

They glide along the building’s edge granting expedient admission.

Sliding or rolling door apparatuses operate through wheels traveling on tracks—serving as pragmatic solutions offering simple entrance methods to facilities.

Double Slide Door and Portal Frame Integration

Essential for enabling the transit of large vehicles or machinery, double slide doors offer functional access to buildings constructed using the post and beam method.

This ensures there are wide, clear openings without sacrificing the structural soundness of the edifice by thoughtfully designing these entrances into a portal frame.

The use of double slide doors is particularly fitting for structures that necessitate regular passage of bulky objects, providing an efficient and pragmatic approach.

The effortless integration of such door systems within a portal structure underscores how post and beam construction techniques can flexibly satisfy diverse operational demands with ease.

Finishing Touches: Aesthetics and Functionality

With their visible wood components, post and beam constructions exude a timeless and warm organic feel. These structures can adapt to a multitude of design preferences, whether one is looking for traditional, modern, or industrial themes, paired with different choices for external finishes.

Trims such as eaves trim, rake trim, and corner trim on metal buildings serve to elevate the aesthetic appeal by introducing added depth and texture.

The strategic placement of windows in steel post and beam edifices fulfills an aesthetic role while also providing practical ventilation options.

In terms of temperature regulation within these buildings, efficient HVAC systems like heat pumps or chilled beams along with displacement ventilation methods offer effective climate control solutions.

Cladding Options and Aesthetic Variability

In post and beam architecture, there are numerous cladding choices that allow for a broad range of visual appeal. Durable and visually attractive exterior wall finishes can be achieved using materials such as red cedar siding coupled with poly-ash trim.

Corrugated metal panels, offering a variety of styles and hues, provide an enduring solution for cladding that is also easy to maintain.

For those who prefer alternatives to the standard options on metal buildings, several other cladding types can be considered.

Stucco

Brick veneer

Stone veneer

Wood

By integrating different facade elements like wood, brick, or metal one can enrich texture and emphasize particular architectural details.

Blending various siding components—for example, combining insulated stucco panels with stacked stone—elevates the building’s external charm through contrasting surfaces.

The use of exposed metal connectors in post and beam structures not only fulfills structural functions but simultaneously contributes an element of design interest.

Summary

To sum up, the world of post and beam steel construction presents a harmonious blend of lasting strength, versatile design possibilities, and visual appeal.

The meticulous fabrication of steel elements and the detailed incorporation of mechanical and electrical systems showcase this method’s precision and flexibility.

This structural system not only encourages architectural innovation but also promises enduring solidity. Depending on final detailing, these buildings can mirror diverse styles – from traditional to modern industrial looks – proving that practicality and beauty can indeed coexist seamlessly within post and beam constructions.

Frequently Asked Questions

What role do columns play in post and beam structures?

In post and beam constructions, the columns are pivotal for conveying loads from the main roof beams to the foundation, offering vertical support that aids in dispersing weight and guaranteeing structural soundness.

What is the importance of secondary framing in load distribution?

Components of secondary framing, such as purlins and girts, play a vital role in diverting loads to the primary structural members, thus guaranteeing efficient load dispersal within construction projects.

What are some access and egress solutions in post and beam structures?

Hydraulic doors, steel bi-fold doors, stack doors, and rolling doors serve as effective access and egress options in post and beam constructions for streamlined entry and departure.

How is insulation integrated in post and beam construction?

Insulation in post and beam construction is effectively incorporated through the utilization of a perimeter and wall covering system.

This design employs foil-faced polyisocyanurate insulation along with continuous foam insulation, which collectively contributes to achieving an elevated total R-value, thereby optimizing the efficacy of the insulation.

What are some cladding options in post and beam constructions?

When choosing cladding for post and beam structures, there are an array of materials at your disposal including red cedar siding, poly-ash trim, corrugated metal panels, stucco, brick veneer, stone veneer, and timber.

It’s important to factor in both the visual appeal you desire as well as the local weather conditions to ensure you select the most suitable option for your build.